- Have Any Question?

- (+880) 017238012739

- enviroco@gmail.com

RURAL WATER

In rural regions, drinking water is often provided by public treatment plants that recover untreated water from dams or river water.

To the present day, due to distance and/or geographical position, innumerable rural regions, particularly all villages in remote areas of developing nations, run out of water from these sources.

It must be acknowledged that water, is not always far get access to, nevertheless a dependable and cost-effective purification system is essential to supply more or less inhabited region.

ANECO® has pioneered a rural water disinfection system that can successfully satisfy the above-mentioned criteria associated with existing methods in collaboration with its partners.

Rural water sources are largely natural, identical or extremely similar to those depicted below.

The drinking water disinfection system is simple and practical, requiring neither elaborate infrastructures nor the installation of sophisticated equipment.

1. Water from the different springs seen above is filtered using basic sand filters, as shown in the schematic below:

2. Once the water has been leached from the sand, it can be disinfected by our system in two manners :

a. The first manner is to directly inject the Aneco® into the water.

b. The second manner is to store Aneco® in a storage tank and distribute it to the network.

An RDX (Redox) meter is used to evaluate disinfection quality, and a brine tank is used to produce Aneco®. ANECO® can treat water anywhere power is accessible, providing rural communities with drinking water that completely conforms with WHO (World Health Organization) quality requirements, with no volumetric restriction on the amount of water that may be treated.

CHEMICAL-FREE DESALINATION

To address the desalination demands of its clients, ANECO® chose to develop innovative chemical-free reverse osmosis systems mounted in containers with a production capacity according to the needs.

PRIOR TO TREATMENT

Desalination:

Desalination by reverse osmosis is required to guarantee low turbidity and to remove suspended bodies or others (e.g. algae) as well as hard components (calcium) and metals from the water.

Filtrations:

A set of qwartz filters made of fiberglass are provided for the filtration phase.

Pressurisation of the pre-feeding skid: Two parallel pumps « with alternate operation » are provided for pressurisation.

Desalination by reverse osmosis

After a preliminary filtering using 5 micron filters and PP fibre cartridges, the liquid is transferred to the filtration stage on semi-permeable membranes, where the water is pressured at roughly 64 bar to get a flow of filtered water. The process requires energy, which is provided by centrifugal or piston-type pressurisation pumps with duplex stainless steel components in direct contact with saltwater and a state-of-the-art energy recovery system.

Two dosing stations, one for anti-scale and one for antioxidant products, contribute to membrane preservation.

The high-pressure line’s hydraulic components are all composed of duplex steel. The membrane containers are constructed of glass resin (fiberglass) and can withstand pressures more than the estimated operating pressure of 64 bar. For pressure pipes, the low pressure circuit is composed of rigid PVC.

Energy recuperation:

The plant is outfitted with a cutting-edge energy recovery technology that transfers energy straight from the high-pressure concentration to the salt water equivalent at the intake.

This technique, when paired with low-pressure-loss membranes and high-efficiency pumps, delivers a considerable decrease in energy usage. This approach ensures that at least 50% of the absorbed electrical energy is saved

Volume of flow:

With the use of already osmotised water, the volume of the flow membranes will be automated and programmable. The system incorporates automated valves for proper flow volume management, which are controlled by the PLC and will pull reverse osmosis water straight from the tank using the pre-feed pump.

Management and control:

The water desalination system is followed by an electrical panel with a touchscreen control and management unit and a modem for remote control and programming. The instrumentation for controlling the different flows and pressures will be carried out with translators that allow digital reading and tracking.

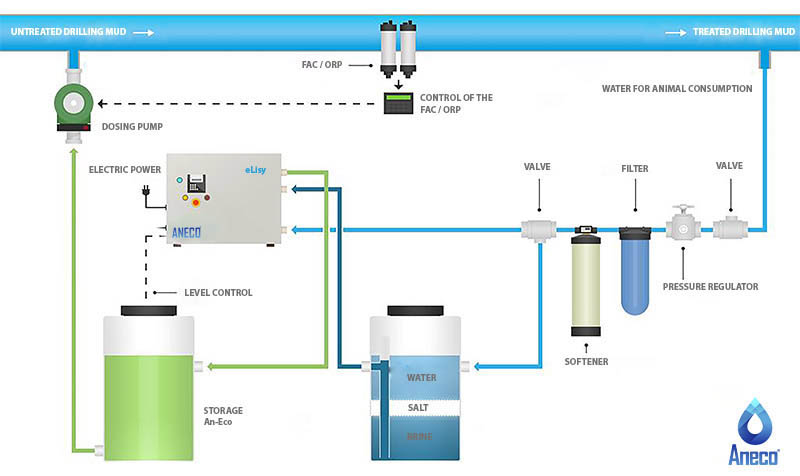

Disinfection system eLisy:

The new eLisy water disinfection system provides purified and drinkable water that is totally clear, owing to algaecide and floculant action that completely eliminates all sorts of bacteria, including legionellosis.

Everything is quite natural. eLisy units are intended for cleaning, disinfection, and sterilisation of systems using 0.05% – 1.0% sodium chloride (NaCl) solutions. The units electrolyze salt water by separating positive and negative ions using ceramic or polymer membranes. Electrochemical processes result in the production of many types of active solutions. The goal is to kill pathogens including bacteria, viruses, spores, molds, and fungus while also cleaning and eliminating heavy metals from the water. However, the advent of multi-resistant bacteria, the discovery of Legionnaires’ disease, and other issues linked with chlorinated substances in recent years have prompted a quest for alternative technologies and methods to disinfect water. ANECO® technologies have enabled the development of Aneco® (HClO) recognized to remove infections by electronic activation; they generate hypochlorous acid, which is also composed of natural sodium hypochlorite ions, with a significant reduction in HAZARDS, COSTS, and ENVIRONMENTAL IMPACT.

Electrochemical processes result in the production of many types of active solutions. The goal is to kill pathogens including bacteria, viruses, spores, molds, and fungus while also cleaning and eliminating heavy metals from the water. However, the advent of multi-resistant bacteria, the discovery of Legionnaires’ disease, and other issues linked with chlorinated substances in recent years have prompted a quest for alternative technologies and methods to disinfect water. ANECO® technologies have enabled the development of Aneco® (HClO) recognized to remove infections by electronic activation; they generate hypochlorous acid, which is also composed of natural sodium hypochlorite ions, with a significant reduction in HAZARDS, COSTS, and ENVIRONMENTAL IMPACT.

. Simple and safe to use

. Effective: reduced contact time for sterilizing

. Biodegradable liquids

. Simplifies operational procedures while providing fast and safe advantages.

Aneco®

The concentration of active sodium hypochlorite (chlorine) in Aneco® (HClO) can be modified as needed by deliberate programming in the manufacturing machine. In the hydraulic section, a flow regulator is attached to halt the eLisy unit in the case of a water shortage and force the machine to resume when water flow is restored.

The eLisy device may be manually halted or reactivated using an on/off switch with a power indication. There are numerous basic types with capacities ranging from 20 to 10,000 l/h, therefore output capacity will vary according on the requirements.

The Aneco® (HClO) generated by ANECO® is stored in a container before being injected into the water supply as needed. The dosing schedule will be determined by the water quality and monitored by a flow meter linked to a dosing pump.

According to thorough research, the Aneco® solution (HClO) is:

Based on extensive studies, the Aneco® solution (HClO) is:

• Eco-friendly;

• Non-toxic to humans, animals, and nature;

• A powerful biocide;

• Safe for sewage and septic systems;

• Efficient biocidal effect even with very fast contact;

• Can be used in all stages of disinfection and cleaning;

• No waste on any type of surface without a possible recommended dosage;

• Can be applied to liquids, hot or cold, on ice, and still in spray form;

• Allergy-tested;

• Produced on-site to reduce chemical storage and handling.