- Have Any Question?

- (+880) 017238012739

- enviroco@gmail.com

OIL AND GAS

Oil and Gas:

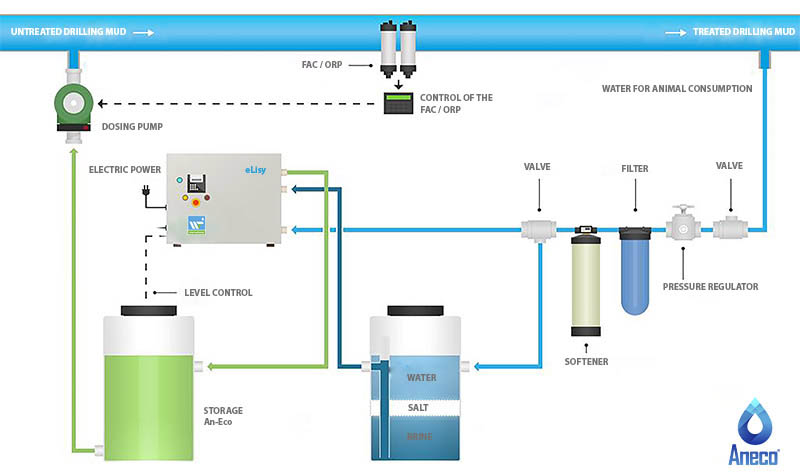

Aneco® and Cateco® solutions have been utilized to stimulate and increase oil and gas production, as well as to improve the performance of drilling fluids.

Aneco® is a very effective alternative to non-biodegradable or bioaccumulative bactericides. It is a selective bactericide that targets the bacteria that cause corrosion and muck created by microorganisms while being safe for humans.

Cateco® has been used to clean drills and equipment on the job site in place of diesel fuel.

Aneco® solutions can be used to boost production in wells afflicted by huge colonies of bacteria and other microbes, eradicating bacteria and removing biomass.

Aneco® solutions may be used to manage bacteria, maintain fracturing fluids and gels, and assure polymer and better performance in water used for fracturing (Frac) of oil and gas wells. Aneco® treatments remove fouling, including sludge, from pipes, and biomass may be removed from cooling water systems, enhancing heat transfer values and preventing corrosion caused by microbial presence (MIC). Water produced can be processed and utilized in stimulation fluids or big water jets.

Recent results from field operations where frac water was treated with Aneco® reveal that bacteria levels in frac water (Frac) were lowered below the threshold level, negatively impacting frac liquids and gels (Frac).

Cateco® has also been demonstrated to significantly lower water surface tension and may be used to induce water used to promote production in wells.

Aneco® shares certain qualities with Cateco® and, being a biocide, is a natural surfactant to some extent. The usage of Aneco® and Cateco® in oil rigs leads in increased oil recovery simply by employing low-cost and environmentally friendly solutions. In addition to the foregoing, Aneco® avoids microbiological contamination of the water injection hole during oil recovery. Aneco® eliminates the need for standard disinfection chemicals, which may be expensive, extremely toxic, and possibly hazardous for shipping and storage.

The injection water’s purity is crucial. To avoid the growth of anaerobic microbes, it must be free of suspended particles and have a low oxygen level.

It is also critical that the water be devoid of anaerobic microorganisms, particularly sulfate-reducing bacteria, which flourish in anaerobic environments by converting existing sulfate ions in hydrogen sulfide gas (H2S).

H2S is highly corrosive and lowers the market value of oil by increasing its sulfide content, causing pipeline corrosion and posing a significant health risk to people.

Applications in oil and gas :

• Fracturing Water (Frac) – To protect fracturing fluids, polymers, and gels, mix 5 liters of Aneco® with 1000 liters of frac water at 2.5 ppm FAC to mitigate and retard the growth of non-public microorganisms such as anaerobic bacteria, aerobic bacteria, and sulfite-reducing bacteria.

• Sour Wells – To control undesired microbes, minimize hydrogen sulfide gas, and restore integrity, gradual dosing 600-650 liters at 500 ppm as FAC of Aneco® in the borehole on a daily or weekly basis.

• Generated water – To prevent the growth of unclean bacteria, combine 21 liters of Aneco® with 1000 liters of generated water at 10.5 ppm FAC.

• Heaters, hydrocarbon storage facilities, and gas storage wells – To treat storage facilities, mix 500-550 liters of Aneco® at 500 ppm FAC in the aqueous phase of the mixed hydrocarbon/water system to inhibit microorganism growth, control hydrogen sulfide formation, and reduce storage tank corrosion.

• Water Flood Water – To treat water flood water, use 21 liters of Aneco® with 1000 liters of injection water at 10.5 ppm FAC to inhibit microbial development and manage sludge nulle pipes.

Important note: The aforementioned dosage regimens are dependent on the source water and may change based on the pollution of treated items, or FAC demand. All of these factors can influence dosage and result in larger Aneco® volumes.

Until recently, the deployment of Enhanced Oil Recovery (EOR) technology was limited by a lack of generators capable of generating high volumes of product (1000 LPH – 6000 LPH). ANECO® designed and serialized such generators from Aneco® / Cateco®.

A typical ANECO® EOR system is highly small and simple to install within plants with minimum downtime. Furthermore, ANECO® EOR technology does not generate undesirable by-products, and the exceptionally low production cost of Aneco® / Cateco® makes its application in the oil and gas business particularly appealing.

This information is derived from publicly available generic data. Aneco® (trade name of ANECO®) processes rely on oil shale rocks and include economically sensitive information.

The same ANECO® disinfection concept may be used to purify drinking water on offshore rigs. After storage, at the point of use, the environmental disinfection system can be employed to eradicate bacteria, molds, yeasts, and fungus that pollute water sources.