- Have Any Question?

- (+880) 017238012739

- enviroco@gmail.com

WASH WATER RECYCLER

CAR WASH WATER TREATMENT PLANT

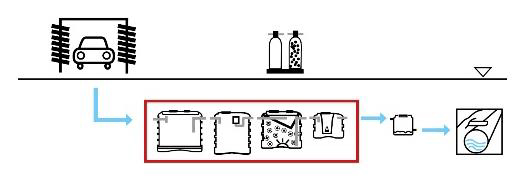

ANECO’s RI system allows the treatment of effluents generated by vehicle and truck washes, in compliance with the EN 858 – 1/2 standard, and adapting the quality of the treated water for reuse during the pre-wash and wash stages. The RI system reduces water consumption in washing operations by up to 98%. As a result, the water resource is conserved and the investment is quickly paid off.

The excess effluent, in this case to be discharged, respects the discharge limits imposed by current legislation with regard to the parameters COD, BOD5, TSS, oil and grease and total hydrocarbons, so it can be discharged directly into the natural receiving environment (water/soil).

Description

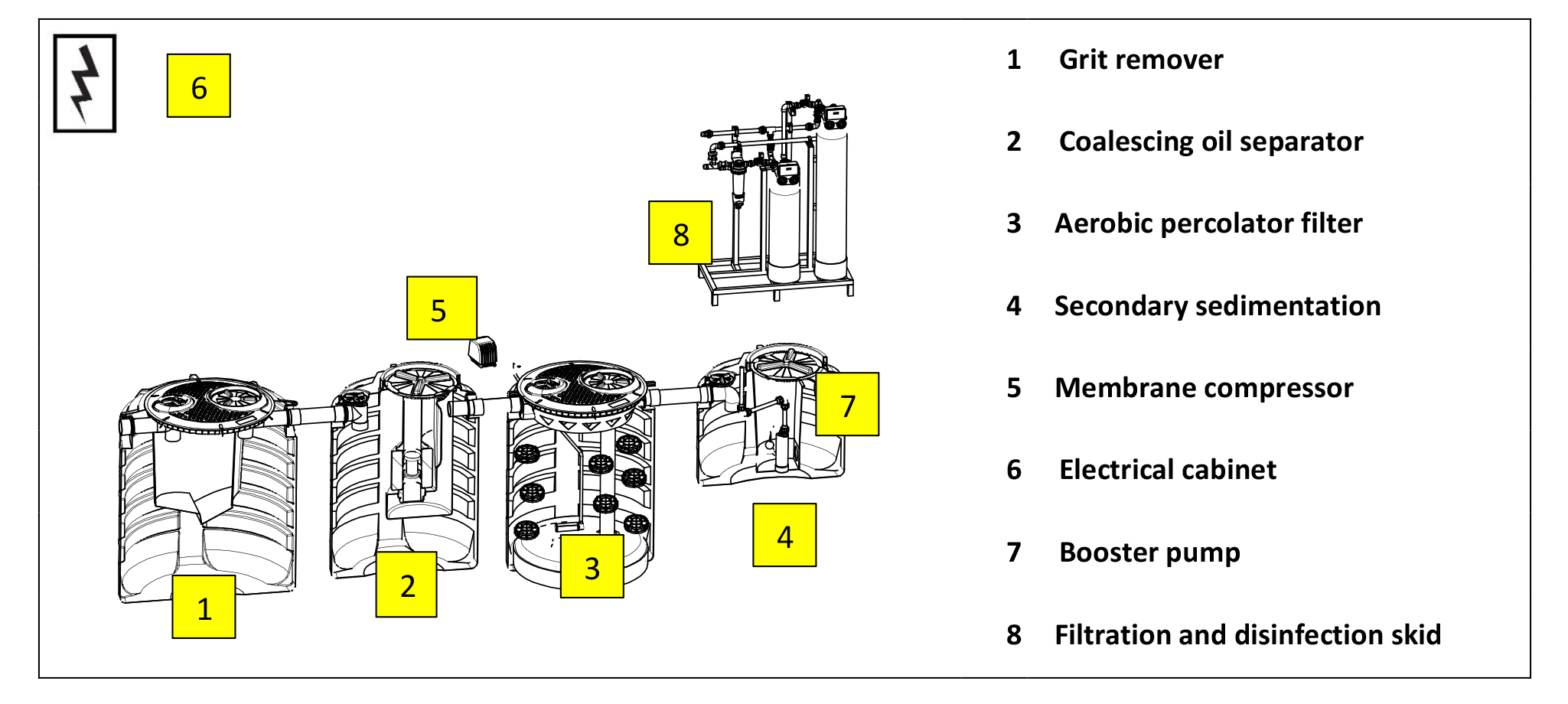

The car wash water treatment plant consists of corrugated polyethylene tanks, which are constructed underground by means of rotational moulding. The plant consists of four separate elements: a coalescence desander, an aerated percolator filter, a final sedimentation tank with accumulation and transfer to the pressure filtration system and a pressure filtration system. The system is complete with an aeration compressor and a timed electrical control panel for the management of the biological purification section (aerated percolator). On a marginal skid (to be installed on the surface), an automatic pressure filtration system is provided on the quartzite and activated carbon filters. The wastewater leaving the plant can be discharged on the ground or reused for initial washing operations. The polyethylene tanks are equipped with vents, PVC inlet and outlet pipes and plugs for inspection and periodic maintenance.

How does it work?

Function and use

The landfill car wash system is used to treat water from manual car wash systems or portals and tunnels that typically contain sand, sludge, various aggregates, biodegradable detergents, drying and polishing product residues, hydrocarbons and trace metals. The flow rate of the influent should never exceed the nameplate flow rate of the system.

These plants consist of a pre-treatment phase in which solids and oils are separated by gravity; a biological treatment and filtration phase carried out in a third tank using an artificially aerated biofiltration process. The effluent is then returned to an automatic pressure filtration system, consisting of a quartzite filter and an activated carbon filter. The overflow from the plant and the backwash water from the filtration system must be directed either to the head of the plant or to the public sewerage system after authorisation by the competent authority.

The benefits

This water treatment plant has many advantages:

. Delivered assembled, installed on a galvanised steel skid, ready for outdoor installation

. Easily connected to electricity and water

. No excavation required, it is an external system (except for storage tanks)

. Low maintenance, in addition to regular inspections, it is sufficient to collect the sludge at least once a year and have it disposed of by specialised companies

. Delivered with certification for discharge to the sewer, supplied with a guarantee

. 98% water reuse