- Have Any Question?

- (+880) 017238012739

- enviroco@gmail.com

AGRICULTURE

With its strong bactericidal properties, ANECO® products have a wide range of agricultural uses. Simultaneously, ANECO® solutions enable significant reductions in harmful emissions at low cost, saving significant money as compared to conventional, typically more expensive approaches.

These solutions are safe and simple to use, and dangerous substances can no longer be kept.

Livestock

• A complete animal husbandry hygiene program.

• Milking equipment sterilization.

• Milking barns and other agricultural structures must be cleaned.

• Teat-dip to manage and diminish somatic cell numbers.

Veterinary medicine

Small, compact equipment that produces a bioactive solution capable of treating a wide range of high bacterial and viral load circumstances, with the goal of providing farmers with fast access to effective therapies. Dysentery, mastitis, hoof fungal diseases, ringworm, respiratory infections, and foot and mouth disease have all been effectively treated with ANECO® treatments.

They also boost animal resistance to viral illnesses and aid in recuperation.

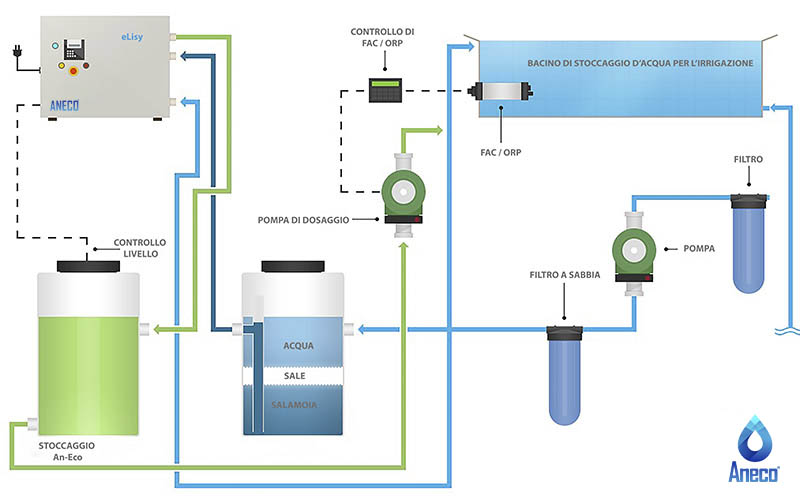

Horticulture and agriculture

The ANECO® solution increases crop yields, disinfects cereals, extends fruit and vegetable shelf life, and purifies irrigation water (crop irrigation and pest management).

It keeps silage fresh and minimizes egg toxicity.

FOOD PROCESSING: SILAGE / GREEN FORAGE PRESERVATION

Aneco®, produced by ANECO® systems, is indicated as a preservative in the preparation and storage of green forage and silage. The use of Aneco® has little impact on the standard green forage / silage preservation technique.

Aneco® functions as a preservative in this application, with no negative effects on the quality of the green forage / silage, which is frequently treated with standard chemical preservatives.

Simultaneously, Aneco® functions as a standard preservative by increasing the acidity of the green forage / silage and cleaning it.

Furthermore, Aneco® aggressively suppresses plant ‘respiration’, resulting in the preservation of numerous vital vitamins that are normally lost when temperatures above 50° C.

Another significant advantage of employing Aneco® is the ability to preserve high-quality green fodder / silage for future consumption independent of moisture, composition, or weather conditions.

Aneco® storage of green forage / silage leads in enhanced product and storage quality.

Consumption of enhanced green forage / silage increases milk production (19%) and weight gain in young animals (42% increase in average daily weight).

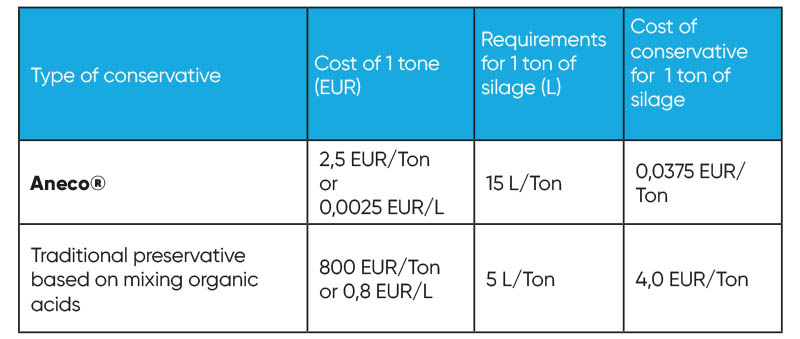

Cost analysis based on the effectiveness of using Aneco® compared to traditional preservative:

Other benefits of using Aneco® for forage/green silage preservation include:

• 95-100% of the forage/green silage may be securely preserved for future use;

• In contrast to conventional chemicals, which are often poisonous, explosive, and leave chemical residues in the forage that make it impossible to use for 2-3 months after processing the forage/green silage, Aneco® is an environmentally safe preservative;

• With Aneco®, we avoid other risks often associated with handling hazardous chemicals;

UNIQUE AND INNOVATIVE – EASY TO USE

The ANECO® diaphragm cell is a round electrolyte reactor made of titanium and rare metals. The electrodes are separated by a polymer or ceramic diaphragm. Even under severe conditions, hardly any element of the cell can be broken or seriously damaged.

Universal diaphragm cell for treating dilute and concentrated aqueous solutions, the heart of any ANECO® unit.

SMALL SIZE – HIGH FLOW RATE

Small in size and portable, all ANECO® cells have a production capacity ranging from 20 l up to 1200 l of Aneco® per hour. Consequently, with just one eLisy unit we can treat and disinfect from 20 – 12000 m3 / h of water and up to 1200 l / h of Aneco® can be dosed.

PERFORMANCE OF THE DIAPHRAGM CELL

In addition to the main electrochemical reaction occurring with the electrodes, the high electric field strength on the electrode surface imparts a degree of electro-meta-stability to the water and its dissolved salts, increasing its ORP in the order of -800mv and + 1200mv respectively in the two flows.

This meta-stable condition remains so for periods of up to 72 hours after treatment and even longer, maintaining an inherently higher reactivity and chemical activity for this period of time and even longer (when properly stored, activated solutions remain highly effective for 6 to 18 months).

The significantly higher ORP than in any other product increases the solubility, dispersive and reactive properties of water and its dissolved salts to an important extent and is a significant indicator of biocidal potential.

The properties of these solutions depend on the electrical characteristics of the feed and the chemical composition of the treated solutions. The pH level of the synthesised solutions is controlled in the pH range 2.5 -13.0, but being adjustable, it can be set for specific parameters.